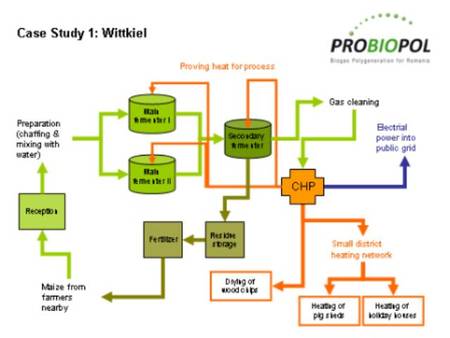

The biogas plant located in the very north of Germany in Stöltebüll is a typical agricultural biogas plant with only a singular input substrate of maize. This kind of mono input is very popular with farmers, who anyway produce feed crops for pigs and cows. Producing additional crops for energetic utilization is thus profitable, if farm land is available. The farmers see that maize production for biogas plant is a profitable business and also an ecological solution for producing electricity and heat. Mono input makes the production of biogas very reliable and continuous. There is no need for a refined composition of input. Thus there are fewer technical problems than in a plant with co-fermentation. Here in Wittkiel, at first, neighbors were afraid of smell and noise. When the plant started operation, they experienced that the smell was not a problem, even with the open residue storage. And the gas motor cannot be heard from more than 100 meters away. Due to the good harvest, experiences shows that biogas plants with maize input have one of the highest output of methane per hectare and also the running cost are one of the lowest.

| Type of plant: |

Agricultural |

| Location: |

Stoltebüll, Germany |

| Operator: |

Biokraft Stenneshöh GmbH & Co. KG |

| Constructor: |

Bioconstruct |

| Operation start: |

November 2006 |

| Mode: |

2 parallel fermenters, secondary fermenter |

| Temperature range: |

Mesophilic |

| Main fermenter: |

2 x 2,217 m3 |

| Secondary fermenter: |

1 x 2,217 m3 |

| Final storage tank: |

1 x 3,400 m3 |

| Feedstock: |

Maize silage |

| Annual amount: |

10,800 tons |

| Use of gas: |

1 CHP with 500 kW el |

| Tpye of CHP: |

GE Jenbacher |

| Electrical output: |

6,328,000 kWh el |

| |

supply for 1,580 households |

| Thermal output: |

6,328,00 kWh |

| |

equals 632,800 l of heating oil |

| Use of thermal energy |

Heating of pig sheds |

| |

pig shed |

| |

holiday houses |

| |

wood chip drying |

| Special feature: |

Exclusive renewable raw material fermentation |

| |

Dry fermentation |

| Investment: |

2 million € |

| Contruction changes: |

Further CHP with 265 kW in 2007 |