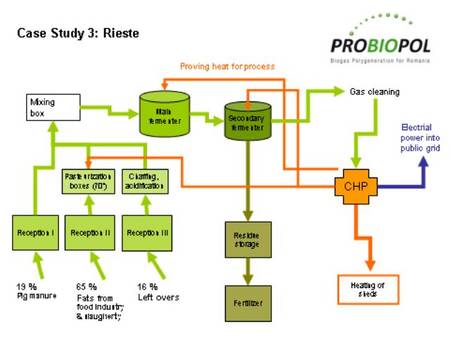

The biogas plant in Rieste near Osnabrück, Germany, was first dimensioned with a 340 KWh electrical CHP output, but received an enlargement to 520 kWh el power later on. The plant produced biogas with a mix of organic inputs - pig manure and maize from agriculture as well as fat wastes and other organic waste from food industry and leftovers. This diversity makes the plant quite independent and flexible. The manure and the maize input come from the pig farm belonging to the operator. For heating the sheds the excess heat is used. Another use of the excess heat is for the necessary pasteurization of the food wastes. Since there are different legal requirements for either food waste (leftovers) and animal products not destined for consumption (slaughter wastes). Leftovers have to be pasteurized at a temperature of 70°C for 60 minutes, whereas slaughter wastes have undergo a treatment at a temperature of 103 °C and 3 bars for at least 20 minutes. Due to this various requirements the plant operates with different reception halls.

| Type of plant: |

Waste fermentation |

| Location: |

Rieste, Germany |

| Operator: |

Private |

| Constructor: |

Bioconstruct |

| Operation start: |

November 2003 |

| Mode: |

2 stage |

| |

2 concrete fermenters switched in turn |

| Temperature range: |

Mesophilic |

| Main fermenter: |

1 x 1,180 m3 |

| Secondary fermenter: |

1 x 1,180 m3 |

| Final storage tanks: |

1 x 2,200 m3 |

| Feedstock: |

Left overs (30%) |

| |

Pig manure (19%) |

| |

Fat extractor (16 %) |

| |

Other wastes (16 %) |

| |

Vegetable fat (12 %) |

| |

Maize (7%) |

| Annual amount: |

12,700 tons |

| Use of gas: |

1 CHP with 520 kW el |

| Electrical output: |

4,400,000 kWh el |

| |

supply for 1,050 households |

| Thermal output: |

4,200,000 kWh |

| |

equals 420,000 l of heating oil |

| Use of thermal energy |

Pasteurization, heating sheds |

| Special feature: |

Processing of leftovers, seperate reception |